www.indo-industry.com

01

'11

Written on Modified on

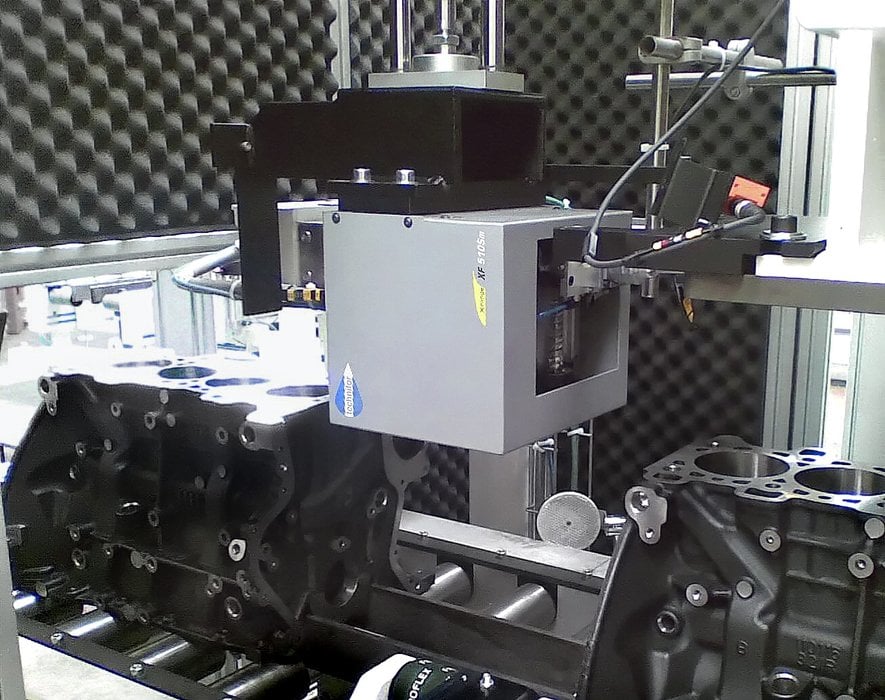

XF510m: a single marking machine for all types of materials

Technifor can offer an electromagnetic micropercussion marking solution for use on all materials. The micro-impacts produced on the material surface using a carbide tipped stylus create a lasting mark, without creating stress or chippings. This new machine is the result of the process to optimise the Technifor range, adding a powerful electromagnet combined with an optimal guide system to produce marking of remarkable precision and quality.

Whatever the nature of the material or the conditions under which it is to be used, this type of marking can produce results which are lasting and cannot be changed. The depth of marking can be as much as 0.2 mm for a large number of metals, thus ensuring totally reliable traceability, even in the toughest environment.

The marking force is fully controlled: the different impacts are precision-controlled, producing light markings on plastic parts or deep markings on steel. Added to this, the stiffness of the mechanical assembly guarantees constant depth and repeatability of the impacts, which will be perfectly aligned by the high-precision guidance system.

The marker heads, which combine lightness, speed and compactness, are easily integrated into all production line layouts (revolving tables, robot arms etc.). Able to be used in all positions, they can be fitted to pedestal tables and fitted with protective grilles or flaps. The multipurpose XF510m range is fitted with a high-amplitude stylus, suitable for all part shapes: flat, convex, concave etc..

The fast turnaround times provided by the machine (as little as 4 seconds for a 10x10 DataMatrix™) mean that it can work in the background, without any negative impact on production line cycle times.

The remote control unit (up to 15 metres away) includes an 18-language interface, can accommodate 14 keyboard types and has a universal power supply compatible with 90 to 250 V. It has a large backlit screen, with user-friendly icons and contextual help, enabling programming of all types of marking: text, logos, variables, time-stamping, counters, 2D codes etc..

This unit is ready for all current communication protocols for added flexibility: Ethernet, USB, RS232 including an interface card with 8 inputs and 4 outputs. It can work autonomously or can be controlled by a PC or programmable logic controller.

The marking force is fully controlled: the different impacts are precision-controlled, producing light markings on plastic parts or deep markings on steel. Added to this, the stiffness of the mechanical assembly guarantees constant depth and repeatability of the impacts, which will be perfectly aligned by the high-precision guidance system.

The marker heads, which combine lightness, speed and compactness, are easily integrated into all production line layouts (revolving tables, robot arms etc.). Able to be used in all positions, they can be fitted to pedestal tables and fitted with protective grilles or flaps. The multipurpose XF510m range is fitted with a high-amplitude stylus, suitable for all part shapes: flat, convex, concave etc..

The fast turnaround times provided by the machine (as little as 4 seconds for a 10x10 DataMatrix™) mean that it can work in the background, without any negative impact on production line cycle times.

The remote control unit (up to 15 metres away) includes an 18-language interface, can accommodate 14 keyboard types and has a universal power supply compatible with 90 to 250 V. It has a large backlit screen, with user-friendly icons and contextual help, enabling programming of all types of marking: text, logos, variables, time-stamping, counters, 2D codes etc..

This unit is ready for all current communication protocols for added flexibility: Ethernet, USB, RS232 including an interface card with 8 inputs and 4 outputs. It can work autonomously or can be controlled by a PC or programmable logic controller.