www.indo-industry.com

27

'10

Written on Modified on

EPLAN Electric P8 2.0

With many new features, such as active device protection, channel oriented PLC design, point wiring and improvements in graphic functions, EPLAN Platform 2.0 ensures greater project reliability, functionality and speed. For this new release, more than 1,000 customer requirements were considered during development.

Version 2.0 takes electrical engineering to a new level, with ongoing time and cost savings and simultaneous support of fluid engineering, process automation, enclosure construction and production.

With EPLAN Electric P8 2.0 deletion is not possible. This applies to devices that can now be protected from changes. It was all too easy to make uncontrolled changes to an item or to delete it by mistake. With the new "protected device" function, all project parts are retained even in the case of graphic delete commands. The same applies for macros: a protected device knows its components, even when all individual parts have not been graphically placed in the macro. This prevents unwelcome surprises as early as in the pre-planning phase. Active protection of project data is freely defined in the parts definitions in the EPLAN platform. This ensures the transparency of extensive project documentation and is also the basis for standardized, efficient design. After the bill of materials is output, incorrect orders and production delays are ruled out.

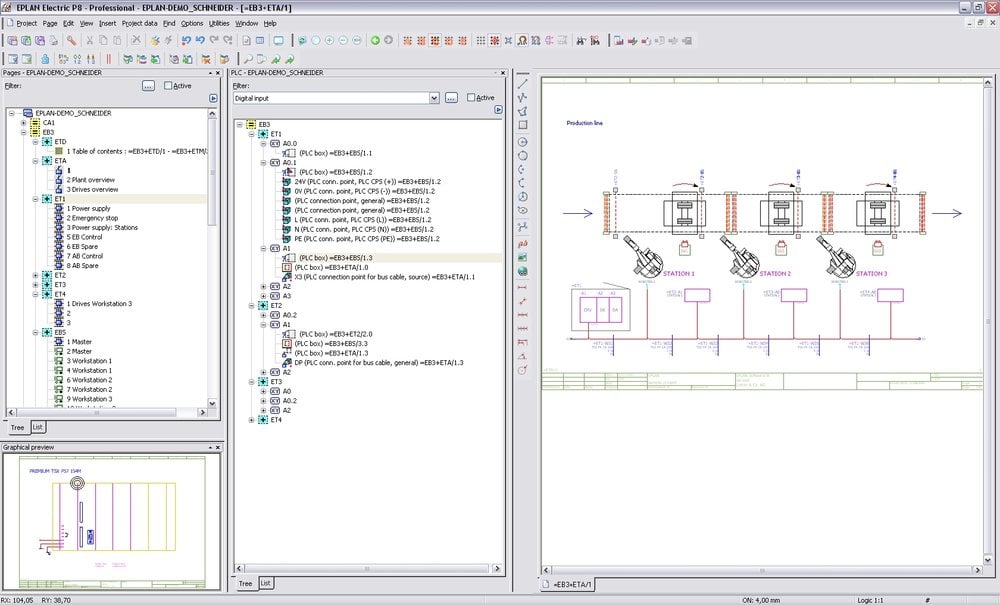

Addresses now are central identifiers - even in PLC design, which is found in all automation concepts today. In addition to graphical oriented or device oriented working methods, PLC components can also be designed in a channel-oriented manner. This makes it easier to keep track of large projects and is consistent with current high-end design working methods. The new PLC navigators also make it easy to select components. They are quickly designed and documented by simply assigning them in the schematic. The PLC component view can be changed at any time.

Another highlight is the new additional 'Netbased Wiring' modul. In EPLAN Electric P8 you will be able to define detailed connections within a network at the database level, irrespective of the graphical representation. In the schematic, logical point wiring instead of target wiring will be shown. Clear representations in the schematic and the simplest of production links can be ideally implemented using this new working method. The advantage of this is that both working methods, netbased wiring and target-oriented wiring, can be used in the project.

More graphic functions are also provided. Extended CAD functions in the area of free graphics now guarantee clear production specifications. Trimming and chamfering as well as perpendicular and tangential design are only some of the functions that support detailed representations for mechanical production. To place graphical objects, XY coordinates can now be directly entered in EPLAN Electric P8. This lets users quickly create operator's desks and flange plates - with all the information needed for trouble-free production.

The new full text filter in parts management lets users use search terms to quickly filter parts masters and select the right component in the tree/list/combination view. Designing is also accelerated at the device level; the full text filter is integrated in the parts master data navigator. This simplifies handling, which is given an enormous boost in the new EPLAN Electric P8. Mini toolbars and detailed icons for toolbars now ensure intuitive handling to the benefit of both professional and occasional users.

Once again, the EPLAN platform demonstrates its practical orientation, which is manifested by its reliability - especially with regard to the new Machinery Directive. The quality of all documentation is guaranteed by online check functions; the system automatically prevents incorrect data from being entered.

Pictures:

protected_device_EN.jpeg: active protection of devices and device configurations in EPLAN Electric P8 prevents unplanned changes and guarantees correct documentation.

netbased_wiring_EN.jpeg: in the schematic, within a network, you can now define logical point wiring at the database level.

With EPLAN Electric P8 2.0 deletion is not possible. This applies to devices that can now be protected from changes. It was all too easy to make uncontrolled changes to an item or to delete it by mistake. With the new "protected device" function, all project parts are retained even in the case of graphic delete commands. The same applies for macros: a protected device knows its components, even when all individual parts have not been graphically placed in the macro. This prevents unwelcome surprises as early as in the pre-planning phase. Active protection of project data is freely defined in the parts definitions in the EPLAN platform. This ensures the transparency of extensive project documentation and is also the basis for standardized, efficient design. After the bill of materials is output, incorrect orders and production delays are ruled out.

Addresses now are central identifiers - even in PLC design, which is found in all automation concepts today. In addition to graphical oriented or device oriented working methods, PLC components can also be designed in a channel-oriented manner. This makes it easier to keep track of large projects and is consistent with current high-end design working methods. The new PLC navigators also make it easy to select components. They are quickly designed and documented by simply assigning them in the schematic. The PLC component view can be changed at any time.

Another highlight is the new additional 'Netbased Wiring' modul. In EPLAN Electric P8 you will be able to define detailed connections within a network at the database level, irrespective of the graphical representation. In the schematic, logical point wiring instead of target wiring will be shown. Clear representations in the schematic and the simplest of production links can be ideally implemented using this new working method. The advantage of this is that both working methods, netbased wiring and target-oriented wiring, can be used in the project.

More graphic functions are also provided. Extended CAD functions in the area of free graphics now guarantee clear production specifications. Trimming and chamfering as well as perpendicular and tangential design are only some of the functions that support detailed representations for mechanical production. To place graphical objects, XY coordinates can now be directly entered in EPLAN Electric P8. This lets users quickly create operator's desks and flange plates - with all the information needed for trouble-free production.

The new full text filter in parts management lets users use search terms to quickly filter parts masters and select the right component in the tree/list/combination view. Designing is also accelerated at the device level; the full text filter is integrated in the parts master data navigator. This simplifies handling, which is given an enormous boost in the new EPLAN Electric P8. Mini toolbars and detailed icons for toolbars now ensure intuitive handling to the benefit of both professional and occasional users.

Once again, the EPLAN platform demonstrates its practical orientation, which is manifested by its reliability - especially with regard to the new Machinery Directive. The quality of all documentation is guaranteed by online check functions; the system automatically prevents incorrect data from being entered.

Pictures:

protected_device_EN.jpeg: active protection of devices and device configurations in EPLAN Electric P8 prevents unplanned changes and guarantees correct documentation.

netbased_wiring_EN.jpeg: in the schematic, within a network, you can now define logical point wiring at the database level.