www.indo-industry.com

07

'08

Written on Modified on

MEDRIX: surgical instrument marking solution

MEDRIX applies permanent direct marking to surgical instruments by micro-percussion. As well as being the market’s least-expensive marking solution for hospitals, MEDRIX features outstanding ease of use and compatibility with sterile environments.

To fight nosocomial diseases with ever-increasing effectiveness and to determine responsibilities in the case of infection, hospitals are all gradually implementing surgical instrument traceability systems. This makes it possible to know where an item is at any time and what it has been used for. Similarly, the instruments that have been used to operate on each patient are identified, with details of their sterilization, storage, etc. All this information is of course managed in real time in the hospital ERP. Instrument traceability also optimizes procurement, inventories, lifetimes and other parameters. In accordance with the procedures of each hospital, reader units are installed for identifying instruments at each step, for example arrival in the operating theatre or sterilization.

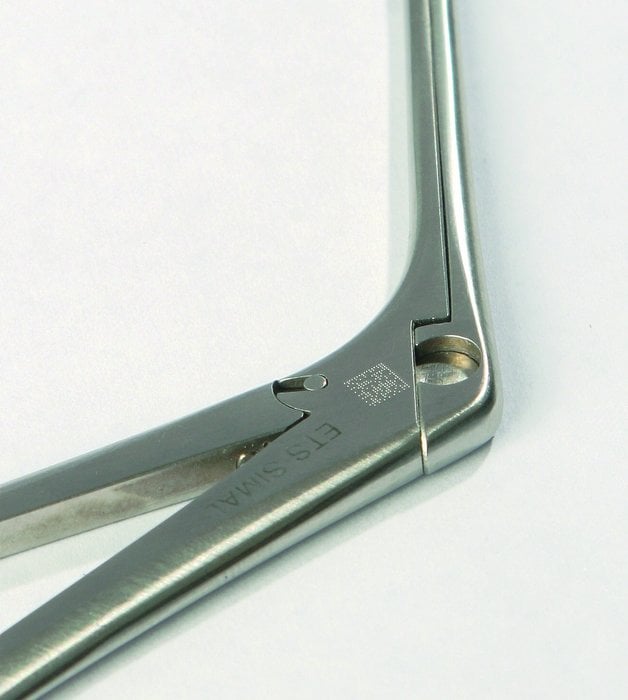

Technifor’s MEDRIX solution marks DataMatrix codes by micro-percussion directly on the instrument. A unique serial number is assigned to each instrument. DataMatrix has the advantages of high information density and easy automatic reading with a video camera. The MEDRIX marking machine has been specially developed by Technifor for hospital uses. Particular emphasis has been placed on simplicity of use and on suitability for sterile environments. First objective: the hospital personnel, who are not familiar with these procedures, must be able to use the system easily. For this purpose a specially designed clamping system is used, consisting of a lever which raises and lowers a clamp to immobilize the instrument. The information to be marked is entered by hand or input from a database. Second objective: the machine must be compatible with a sterile environment. To this end the marking machine is fully enclosed in a stainless steel casing; all the wiring is inside the casing, leaving none visible. The MEDRIX Check table-top reader is also hermetically sealed and made of stainless steel.

The use of micro-percussion direct marking technology offers a number of advantages. First, it eliminates the risks of loss of marking of self-adhesive label systems. Second, as there are no consumables, marking costs decrease with the number of instruments marked, in contrast to RFID or self-adhesive label systems, which need a consumable (chip or label) for each marking.

Two reading solutions are available: the MEDRIX Check sealed table-top reader or conventional wired or Bluetooth handheld readers. MEDRIX Check is compatible with all DataMatrix codes, even codes with low contrast. Very simple to use, it operates continuously and does not require manual triggering.

Further information: www.technifor.com/medical

Technifor’s MEDRIX solution marks DataMatrix codes by micro-percussion directly on the instrument. A unique serial number is assigned to each instrument. DataMatrix has the advantages of high information density and easy automatic reading with a video camera. The MEDRIX marking machine has been specially developed by Technifor for hospital uses. Particular emphasis has been placed on simplicity of use and on suitability for sterile environments. First objective: the hospital personnel, who are not familiar with these procedures, must be able to use the system easily. For this purpose a specially designed clamping system is used, consisting of a lever which raises and lowers a clamp to immobilize the instrument. The information to be marked is entered by hand or input from a database. Second objective: the machine must be compatible with a sterile environment. To this end the marking machine is fully enclosed in a stainless steel casing; all the wiring is inside the casing, leaving none visible. The MEDRIX Check table-top reader is also hermetically sealed and made of stainless steel.

The use of micro-percussion direct marking technology offers a number of advantages. First, it eliminates the risks of loss of marking of self-adhesive label systems. Second, as there are no consumables, marking costs decrease with the number of instruments marked, in contrast to RFID or self-adhesive label systems, which need a consumable (chip or label) for each marking.

Two reading solutions are available: the MEDRIX Check sealed table-top reader or conventional wired or Bluetooth handheld readers. MEDRIX Check is compatible with all DataMatrix codes, even codes with low contrast. Very simple to use, it operates continuously and does not require manual triggering.

Further information: www.technifor.com/medical