www.indo-industry.com

04

'10

Written on Modified on

Modular bearing system for planetary Wind turbine gearboxes

Most wind turbines use gearboxes to transform the relatively low rotational speed of the main shaft into higher speeds required for power generation. Wind turbine designers have to face 2 main challenges when defining these gearboxes. First, the forces a wind turbine gearbox has to transmit are forever increasing while the gearbox itself has to remain compact. Second, these gearboxes are difficult and costly to design, to manufacture and to maintain.

Compact gearboxes

Single- or two-stage planetary gearboxes are commonly used. The utilized bearings for this specific application are among the highest-loaded.

In modern gearboxes an integrated planetary bearing arrangement is used in which cylindrical roller bearings without an outer ring are fitted in the planetary gears, with the bore of the gear forming the outer raceway. This helps to save space in the gearbox but requires a very precise tolerance definition. This is even more challenging for 3 or 4 bearings in a row.

A modular system to simplify gearbox design

NKE has developed a modular solution for wind turbine gearboxes based on single-row cylindrical roller bearings of the RN range, which do not have an outer ring. These bearings are equipped with a one-piece solid brass cage, which is guided by the inner ring (MPB).

These single row bearings can be assembled to sets of two, three or four bearings (see Fig.) to conform to the individual load and design parameters of a specific gearbox.

The design of the gearbox can thus be simplified – instead of using different bearings for different planetary stages as well as for different types of gearbox; the manufacturer can better use only one type of bearing in different combinations.

The new concept offers the advantages of a standardization of the bearings used in this application, a reduced diversity of parts and simplified logistics. NKE supplies ready-to-install matched bearing sets. The tightly toleranced overall height of each individual bearing and their precise matching ensures an even distribution of the radial loads. Each bearing set includes the components required to secure the bearings axially in the planetary gears – such as retaining rings and loose rib rings. If required, the overall width of each bearing set can be adapted to the operating conditions and the available space with spacer rings fitted between the individual bearings.

Used consistently throughout the gearbox assembly, the modular concept has numerous advantages for the user: the design of planetary bearings is simplified; the bearing design can be standardised for the first and second gear stage and across various gearbox sizes; the required number of bearing variants is reduced; the modular design simplifies the adaptation of bearing set characteristics to the requirements of each gear stage.

Maintenance is reduced. The one-piece solid brass cage provides excellent rolling element guidance even during rapid acceleration and the lubrication grooves provided as standard improve the lubrication of the planetary gear bearings. It also features inspection grooves for endoscopic control of the inner raceways as standard. Of course, spare parts management is simplified.

The system is already in use in the 1.5 MW, 2 MW and 2.5 MW wind turbine gearboxes of a well-known German gearbox manufacturer. NKE has supplied these modular bearing systems with bore diameters of 160mm, 190 mm and 200 mm. Bore diameter 220 mm is in project stage. Depending on customer requirements and available space, cylindrical roller bearings of series 3, 22 and 23 are used as the basis, especially when existing bearing solutions are being replaced.

NKE engineering services, based in Austria, will define the clearance of the bearing system in cooperation with customers, because this is determined by bore diameter as well as the tolerances of the planetary wheel.

Each bearing set is packaged as a unit and is marked to prevent inadvertent swapping of matched components within each set. All sets are subjected to a stringent quality inspection of their functional characteristics before leaving NKE’s factory in Steyr.

Besides rolling bearings for wind turbine gearboxes, Austrian bearing specialist NKE develops and produces standard and special bearings for all industrial applications and provides product development, application engineering and a full range of technical, consulting, documentation and training services. NKE’s products are distributed through 15 international representative offices and more than 240 distribution outlets in 60 countries.

Authors:

Daniel Thalmann, team leader in the Application Engineering of NKE AUSTRIA GmbH, is responsible for ensuring first-rate technical support for customers.

Design team leader Faruk Duskunovic, together with his design team at NKE, is responsible for creating the drawings of the specified product features and of new design ideas for standard and special bearings.

Picture 1: Fourfold planetary gear bearing set from NKE

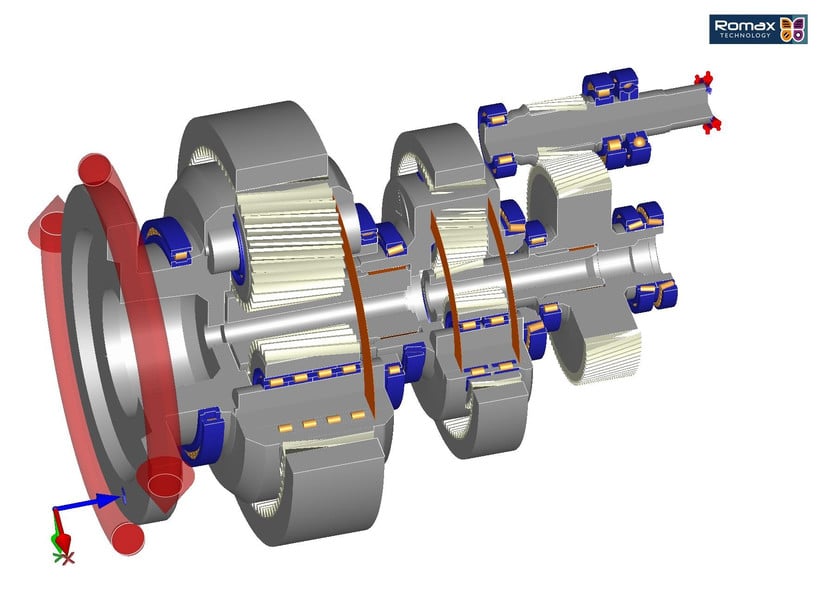

Picture 2: Schematic cutaway drawing of a two-stage planetary gearbox with one spur gear stage (source: Romax/NKE)

Single- or two-stage planetary gearboxes are commonly used. The utilized bearings for this specific application are among the highest-loaded.

In modern gearboxes an integrated planetary bearing arrangement is used in which cylindrical roller bearings without an outer ring are fitted in the planetary gears, with the bore of the gear forming the outer raceway. This helps to save space in the gearbox but requires a very precise tolerance definition. This is even more challenging for 3 or 4 bearings in a row.

A modular system to simplify gearbox design

NKE has developed a modular solution for wind turbine gearboxes based on single-row cylindrical roller bearings of the RN range, which do not have an outer ring. These bearings are equipped with a one-piece solid brass cage, which is guided by the inner ring (MPB).

These single row bearings can be assembled to sets of two, three or four bearings (see Fig.) to conform to the individual load and design parameters of a specific gearbox.

The design of the gearbox can thus be simplified – instead of using different bearings for different planetary stages as well as for different types of gearbox; the manufacturer can better use only one type of bearing in different combinations.

The new concept offers the advantages of a standardization of the bearings used in this application, a reduced diversity of parts and simplified logistics. NKE supplies ready-to-install matched bearing sets. The tightly toleranced overall height of each individual bearing and their precise matching ensures an even distribution of the radial loads. Each bearing set includes the components required to secure the bearings axially in the planetary gears – such as retaining rings and loose rib rings. If required, the overall width of each bearing set can be adapted to the operating conditions and the available space with spacer rings fitted between the individual bearings.

Used consistently throughout the gearbox assembly, the modular concept has numerous advantages for the user: the design of planetary bearings is simplified; the bearing design can be standardised for the first and second gear stage and across various gearbox sizes; the required number of bearing variants is reduced; the modular design simplifies the adaptation of bearing set characteristics to the requirements of each gear stage.

Maintenance is reduced. The one-piece solid brass cage provides excellent rolling element guidance even during rapid acceleration and the lubrication grooves provided as standard improve the lubrication of the planetary gear bearings. It also features inspection grooves for endoscopic control of the inner raceways as standard. Of course, spare parts management is simplified.

The system is already in use in the 1.5 MW, 2 MW and 2.5 MW wind turbine gearboxes of a well-known German gearbox manufacturer. NKE has supplied these modular bearing systems with bore diameters of 160mm, 190 mm and 200 mm. Bore diameter 220 mm is in project stage. Depending on customer requirements and available space, cylindrical roller bearings of series 3, 22 and 23 are used as the basis, especially when existing bearing solutions are being replaced.

NKE engineering services, based in Austria, will define the clearance of the bearing system in cooperation with customers, because this is determined by bore diameter as well as the tolerances of the planetary wheel.

Each bearing set is packaged as a unit and is marked to prevent inadvertent swapping of matched components within each set. All sets are subjected to a stringent quality inspection of their functional characteristics before leaving NKE’s factory in Steyr.

Besides rolling bearings for wind turbine gearboxes, Austrian bearing specialist NKE develops and produces standard and special bearings for all industrial applications and provides product development, application engineering and a full range of technical, consulting, documentation and training services. NKE’s products are distributed through 15 international representative offices and more than 240 distribution outlets in 60 countries.

Authors:

Daniel Thalmann, team leader in the Application Engineering of NKE AUSTRIA GmbH, is responsible for ensuring first-rate technical support for customers.

Design team leader Faruk Duskunovic, together with his design team at NKE, is responsible for creating the drawings of the specified product features and of new design ideas for standard and special bearings.

Picture 1: Fourfold planetary gear bearing set from NKE

Picture 2: Schematic cutaway drawing of a two-stage planetary gearbox with one spur gear stage (source: Romax/NKE)