www.indo-industry.com

23

'10

Written on Modified on

MSR Turning table drive solutions

MSR dramatically simplifies the turning table mechanical transmission system. In many cases, it is also much more economical.

Up to now, the most conventional solution for turntable drives has been composed of: a main drive (single pinion) for turning operation and a feed-preload gearbox (Dual pinions) for C axis drive milling operations. This complex and rather expensive gearbox allows additional operations such as milling.

In this configuration, a main drive provides the total driving torque, which is transmitted continuously to the table which holds the spindle. It is generally composed of a spur-gearbox including a 2-speed gearbox to extend the constant power range according to work piece diameters min/max. It delivers high torque at low speeds to slug out steel or cast iron and permits high speeds for trim or finish cuts.

C-axis drive provides total driving torque 100% at low speed for milling operations. The two pinions need to be disconnected during turning operation and the main drive need to be shifted onto neutral ratio.

REDEX ANDANTEX is introducing a new solution to the market. It benefits from new drive and control systems (for example Siemens CNC or Fanuc).

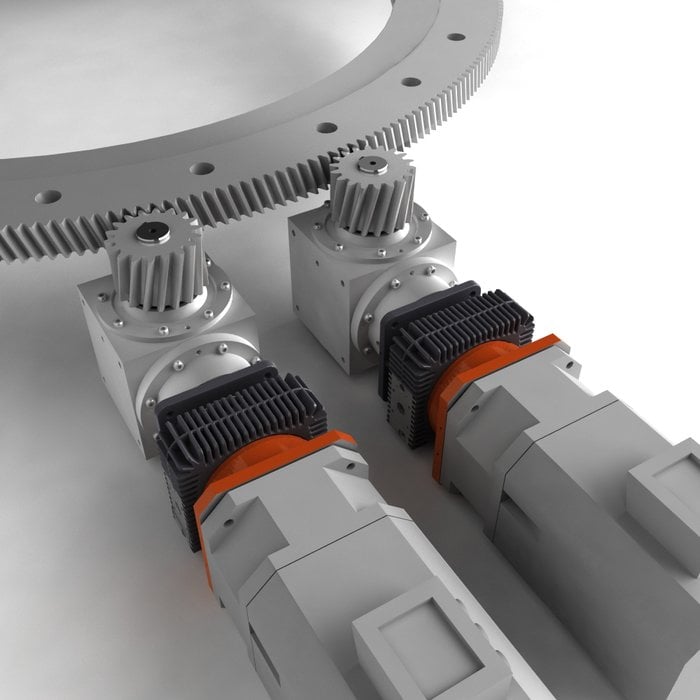

Main drive is composed of two identical gearboxes (Twin pinions) sharing the driving torque (50%-50%) during turning operations. The CNC system manages a motor preload torque to cancel backlash. One motor is driving and the other motor is braking during milling operations.

Because, it enables very accurate positioning, it allows for the execution of additional duties on the C axis, without any additional mechanical device.

For this new drive solution, REDEX ANDANTEX has developed a turnkey solution made with MSD 2-speed gearbox combined with the R SERIE bevel box. This integrated and compact system is ready to be implemented. Depending on machine arrangement, OEM can use bevel box as an option.

This new range consist of 4 sizes, MSD35R31- MSD35R41- MSD60R41- MSD60R51 with torque capacity at pinion from 2000/4000Nm (2 x 40Kw motors) up to 9000/18000Nm (2 x 100Kw motors) with two possible ratios of 7.66&2 and 9.88&2.

This solution, combined with pinion/ring ratio of about 10 to 15 offers:

- Turn table torques from 20 0000Nm up to 270 000Nm

- Global ratios (gearbox + ring gear) of 77/20 and 148/30

For new turning table developments, this solution is much simpler and economical. In particular, it eliminates the need for developing a complex and expensive gearbox for the C axis.

For existing systems, it also offers numerous advantages. A solution with two motors is much less expensive and easier to manage. In the case of a high duty turning table in the conventional configuration a 160kW motor, the MSR would use two 80kW motors, which are more standard and less expensive, despite the fact that there are two of them. Spare parts management is also much easier to manage with a smaller motor. Further, there is no need to manage the C-axis gearbox manufacturing with all its components.

In this configuration, a main drive provides the total driving torque, which is transmitted continuously to the table which holds the spindle. It is generally composed of a spur-gearbox including a 2-speed gearbox to extend the constant power range according to work piece diameters min/max. It delivers high torque at low speeds to slug out steel or cast iron and permits high speeds for trim or finish cuts.

C-axis drive provides total driving torque 100% at low speed for milling operations. The two pinions need to be disconnected during turning operation and the main drive need to be shifted onto neutral ratio.

REDEX ANDANTEX is introducing a new solution to the market. It benefits from new drive and control systems (for example Siemens CNC or Fanuc).

Main drive is composed of two identical gearboxes (Twin pinions) sharing the driving torque (50%-50%) during turning operations. The CNC system manages a motor preload torque to cancel backlash. One motor is driving and the other motor is braking during milling operations.

Because, it enables very accurate positioning, it allows for the execution of additional duties on the C axis, without any additional mechanical device.

For this new drive solution, REDEX ANDANTEX has developed a turnkey solution made with MSD 2-speed gearbox combined with the R SERIE bevel box. This integrated and compact system is ready to be implemented. Depending on machine arrangement, OEM can use bevel box as an option.

This new range consist of 4 sizes, MSD35R31- MSD35R41- MSD60R41- MSD60R51 with torque capacity at pinion from 2000/4000Nm (2 x 40Kw motors) up to 9000/18000Nm (2 x 100Kw motors) with two possible ratios of 7.66&2 and 9.88&2.

This solution, combined with pinion/ring ratio of about 10 to 15 offers:

- Turn table torques from 20 0000Nm up to 270 000Nm

- Global ratios (gearbox + ring gear) of 77/20 and 148/30

For new turning table developments, this solution is much simpler and economical. In particular, it eliminates the need for developing a complex and expensive gearbox for the C axis.

For existing systems, it also offers numerous advantages. A solution with two motors is much less expensive and easier to manage. In the case of a high duty turning table in the conventional configuration a 160kW motor, the MSR would use two 80kW motors, which are more standard and less expensive, despite the fact that there are two of them. Spare parts management is also much easier to manage with a smaller motor. Further, there is no need to manage the C-axis gearbox manufacturing with all its components.