www.indo-industry.com

13

'10

Written on Modified on

Weidmüller OMNIMATE POWER HYBRID SV/BVF 7.62 connectors for printed circuit boards. – In only one operation, the plug connector connects the energy and signal lines as well as the braided shielding of hybrid cables

At this year’s SPS/IPC/DRIVES, Weidmüller introduces an innovative generation of printed circuit board connectors for drive systems and components. OMNIMATE POWER HYBRID SV/BVF 7.62 connectors for printed circuit boards connect the energy and signal lines as well as the braided shielding of a device in only one operation, locking automatically.

Hybrid cables establish the connection – motor-outlet – between frequency converter or servo-converter and the motor. The new hybrid plug connectors combine innovative and application-based details to a holistic solution allowing the simultaneous, safe and “blind” connection of energy, signals and shielding. Typical examples are the pluggable shielding or the single-hand locking with snap-on automatic. The integration of these functions allows the intuitive and tool-free operation as well as permanently save contact, even under difficult conditions. The innovative braided shielding ensures a reliable and stable protection of electronics and data communication against electro-magnetic interference.

The new power hybrid connector SV/VBF 7.62 with its integrated signal contacts, pluggable shield connection and the single-hand safety lock makes up for three single components and reduces three separate operations to one. It offers the solution for typical challenges regarding the design:

1. Pitch-exact integration of the signal contacts into the power element allowing better miniaturisation, respectively packaging density on the printed board and the device front. One single plug operation facilitates the assembly, commissioning and maintenance of a device.

2. The pluggable shield connection with a female multipoint connector replaces two bolt flanges. The innovative constructional detail guarantees safe EMC shielding. Exterior and interior braided shielding are automatically contacted via the pluggable female multipoint connector, independent from the operator. No contact flanges are needed thus saving maximum space.

3. Single-hand safety lock: The tool-free snap-on lock is placed in the middle and replaces two bolt flanges. A safe and reliable locking is effected automatically and independent of the operator. The integration of the signal contacts (without alteration of the connector dimensions) allows space reductions for both, device and printed circuit board. The intuitive connection of all four functions (energy, signals, shielding and locking) can be effected in one operation – even in case of obstructed view and under difficult conditions.

The integration of multiple functions concerning energy and signal contacts as well as the pluggable shielding contact and automatic locking system contribute to a significant cost reduction regarding manufacturing, installation and maintenance. And there are further advantages:

- short installation and maintenance times,

- reduction of device dimensions and

- less space required in the control cabinet

The distance between different lines of devices can be reduced by up to 10 cm, because an inclination of 30° of the conductor outlet allows an easy and slim arrangement of the wiring. The pluggable shielding contact plate needs considerably less space for mounting than conventional bolt flanges.

All in all, the plant availability can effectively be increased due to the innovative shielding contact plate, the single-hand safety lock and the integrated signal contacts.

The new generation of OMNIMATE POWER HYBRID plug connectors for printed circuit boards features PUSH IN connection technology. This innovative connection technology allows fast prefabrication and installation of hybrid cables. With “PushIn”, solid or flexible conductors with wire end ferrules can simply be “pushed” into the clamping point.

Key word: Weidmüller OMNIMATE POWER HYBRID SV/BVF

For more information: www.weidmueller.com

Captions:

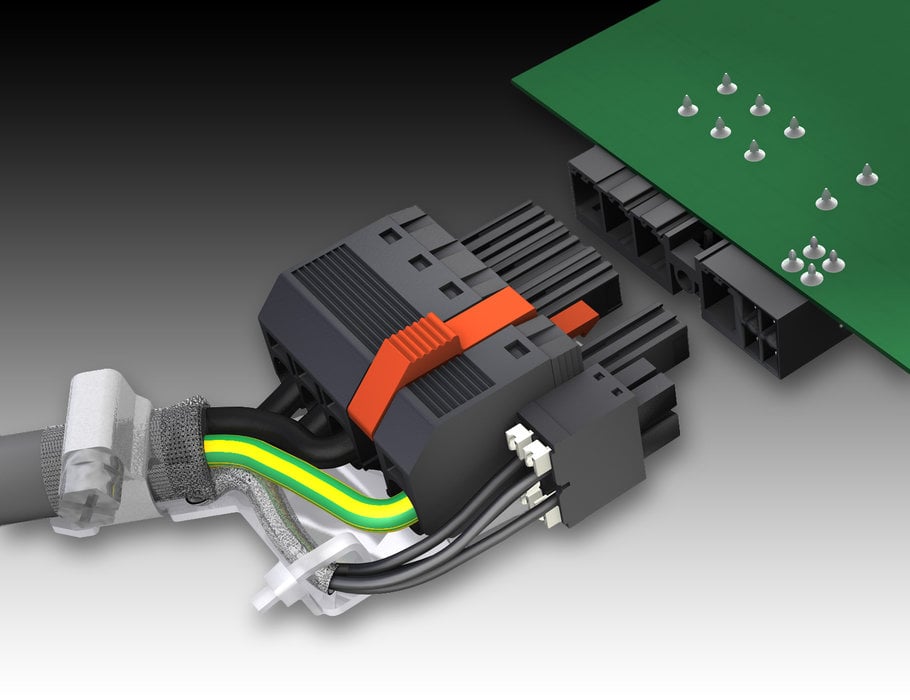

Figure 1: Weidmüller OMNIMATE POWER HYBRID SV/BVF 7.62

connector for printed circuit boards. – The power hybrid connector for printed circuit boards connects the energy and signal lines as well as the braided shielding of hybrid cables in only one operation. A single-hand safety lock (in middle position) serves as central locking system (red design).

Fig. No.1: Hybrid_not_plugged

Figure 2: Weidmüller OMNIMATE POWER HYBRID SV/BVF 7.62 connector for printed circuit boards. – The power hybrid connector for printed circuit boards is made for a slim cable conduct due to an inclination of 30° of its cable outlets. This constructional detail allows compact devices. The distance between two lines of devices can be reduced by up to 10 cm.

Fig. No.2: Hybrid_Applikation

The new power hybrid connector SV/VBF 7.62 with its integrated signal contacts, pluggable shield connection and the single-hand safety lock makes up for three single components and reduces three separate operations to one. It offers the solution for typical challenges regarding the design:

1. Pitch-exact integration of the signal contacts into the power element allowing better miniaturisation, respectively packaging density on the printed board and the device front. One single plug operation facilitates the assembly, commissioning and maintenance of a device.

2. The pluggable shield connection with a female multipoint connector replaces two bolt flanges. The innovative constructional detail guarantees safe EMC shielding. Exterior and interior braided shielding are automatically contacted via the pluggable female multipoint connector, independent from the operator. No contact flanges are needed thus saving maximum space.

3. Single-hand safety lock: The tool-free snap-on lock is placed in the middle and replaces two bolt flanges. A safe and reliable locking is effected automatically and independent of the operator. The integration of the signal contacts (without alteration of the connector dimensions) allows space reductions for both, device and printed circuit board. The intuitive connection of all four functions (energy, signals, shielding and locking) can be effected in one operation – even in case of obstructed view and under difficult conditions.

The integration of multiple functions concerning energy and signal contacts as well as the pluggable shielding contact and automatic locking system contribute to a significant cost reduction regarding manufacturing, installation and maintenance. And there are further advantages:

- short installation and maintenance times,

- reduction of device dimensions and

- less space required in the control cabinet

The distance between different lines of devices can be reduced by up to 10 cm, because an inclination of 30° of the conductor outlet allows an easy and slim arrangement of the wiring. The pluggable shielding contact plate needs considerably less space for mounting than conventional bolt flanges.

All in all, the plant availability can effectively be increased due to the innovative shielding contact plate, the single-hand safety lock and the integrated signal contacts.

The new generation of OMNIMATE POWER HYBRID plug connectors for printed circuit boards features PUSH IN connection technology. This innovative connection technology allows fast prefabrication and installation of hybrid cables. With “PushIn”, solid or flexible conductors with wire end ferrules can simply be “pushed” into the clamping point.

Key word: Weidmüller OMNIMATE POWER HYBRID SV/BVF

For more information: www.weidmueller.com

Captions:

Figure 1: Weidmüller OMNIMATE POWER HYBRID SV/BVF 7.62

connector for printed circuit boards. – The power hybrid connector for printed circuit boards connects the energy and signal lines as well as the braided shielding of hybrid cables in only one operation. A single-hand safety lock (in middle position) serves as central locking system (red design).

Fig. No.1: Hybrid_not_plugged

Figure 2: Weidmüller OMNIMATE POWER HYBRID SV/BVF 7.62 connector for printed circuit boards. – The power hybrid connector for printed circuit boards is made for a slim cable conduct due to an inclination of 30° of its cable outlets. This constructional detail allows compact devices. The distance between two lines of devices can be reduced by up to 10 cm.

Fig. No.2: Hybrid_Applikation