www.indo-industry.com

12

'09

Written on Modified on

Nicolás Correa chooses new Redex Andantex ‘KRPX’ rack&pinion drives for its new range of bridge-type milling machines

For its new range of VERSA milling machines, Nicolás Correa has adopted for both X and Y linear axis the TwinDrive rack & pinion drives from REDEX ANDANTEX. Electrically preloaded, this linear drive system achieves unique precision for such huge machine-tools.

Pic 1: Correa|VERSA bridge-type milling machine with travelling table

With their reliability Nicolás Correa’s milling and boring machines continue to be the best market response to machining requirements that reconcile highest performance and versatility at a competitive cost. Nicolás Correa, with more than 600 bridge-type milling machines working worldwide, becomes in the European leader in the manufacture and this type of machines and one of most recognised in the world.

With their reliability Nicolás Correa’s milling and boring machines continue to be the best market response to machining requirements that reconcile highest performance and versatility at a competitive cost. Nicolás Correa, with more than 600 bridge-type milling machines working worldwide, becomes in the European leader in the manufacture and this type of machines and one of most recognised in the world.

The gantry architecture represents the best balance between the dynamic behaviour of the machine and the level of precision it can achieve. In addition to the well-known “robustness” of their machine, Nicolás Correa is set apart in 5-axis milling, thanks to their experience and their technical know-how.

Nicolás Correa has just updated its current range of bridge-type milling machines with the new high-performance family called VERSA.

This model is equipped with a full range of interchangeable heads, among which is the mechanical universal head with a resolution of 0.02º and a rated speed of 6,000 rpm (UAD). This patented head offers better repeatability and locking force than conventional systems.

High performances linear drives in a wide range of bridge type machines

Worthy of note is the Correa | VERSA travelling table model, which has a work area of up to 14,500 x 5,000 x 1,500 mm. The Correa | VERSA M travelling bridge version and its variant the Correa | VERSA MW with adjustable crossbeam offers even greater versatility for the optimal machining of large structural elements and tools while retaining the rigidity and precision specific to the gantry architecture.

This new family of bridge-type machines incorporates the most recent advances on the market in terms of the guide systems and drives of the different axes, as well as the structural elements that offer greater dynamics, precision and damping in machining work. Using the most appropriate drive system is therefore a keypoint and Nicolás Correa has found in REDEX ANDANTEX a specialist supplier of rack & pinion drive systems for machine tools. The X and Y axes are therefore fitted in standard with this manufacturer’s drive systems.

Exceptional technical features

On the X axis, these drives are capable of moving a mass of 50 Tn with an acceleration of 1.8 m/s2, although they are capable of moving a mass of 70 Tn depending of the customer’s needs. Speeds in the X and Y axes are 30 m/min.

To cancel out backlash in the 2 axes, Nicolás Correa has opted for the TwinDrive system. It consists of a master-slave electronic configuration (electrical preload), with 2 motors.

The rigidity of the reducers together with the “true integrated pinion concept” (REDEX ANDANTEX patent) provides to Versa machine incomparable KV values to the CNC:

X-axis: KV=1 with 50000 kg of moving mass

Y-axis: KV=2 with 9200 Kg of moving mass

As a consequence, machine is able to reach the highest dynamic levels and optimal control response, resulting in greater positioning precision. A closed-loop system is implemented thanks to a Heidenhain linear encoder achieving following features:

X-axis: repeatabily = 5 microns ; Precision = 7 microns

Y-axis: repeatabily= 4 microns ; Precision = 6 microns

Versa X axis moves with an acceleration of 1.8 m/s2, a 50t travelling table with a repeatability of 5 microns

Concurrent development and multiple partnerships

The racks are manufactured by Swiss company Güdel, REDEX ANDANTEX business partner in a number of countries, such as Spain. High precision racks are the perfect technological partner for the servo-reducers, providing the lowest pitch error on the market in tempered and rectified commercial racks.

“With this new range of milling machines, we have incorporated REDEX ANDANTEX rack & pinion drives in the Y axis for the first time and proven that interpolation with the X axis has improved compared with the previous ball screw solution” – explains Javier Hernando, I+D Director of Nicolás Correa.

Nicolás Correa also fits REDEX ANDANTEX rack & pinion drive systems in the high-speed floor-type HVM-HS moving column milling machines of the ANAYAK range. This range is designed for machining medium and large-sized parts.

“Working with REDEX ANDANTEX, we have found the perfect partner that meets our expectations, not only in terms of product quality and reliability, but also in terms of their before- and after-sales service, which provides us with significant added value” – remarks Javier Hernando.

A new mounting concept allowing much simpler assembly

Amongst other machine-tools OEMs, the answer to Nicolas CORREA’s needs in terms of racks & pinions drive systems did lead REDEX ANDANTEX to increase its TwinDrive range of products with the new KRPX. This new version will be officially introduced during the next EMO 2009.

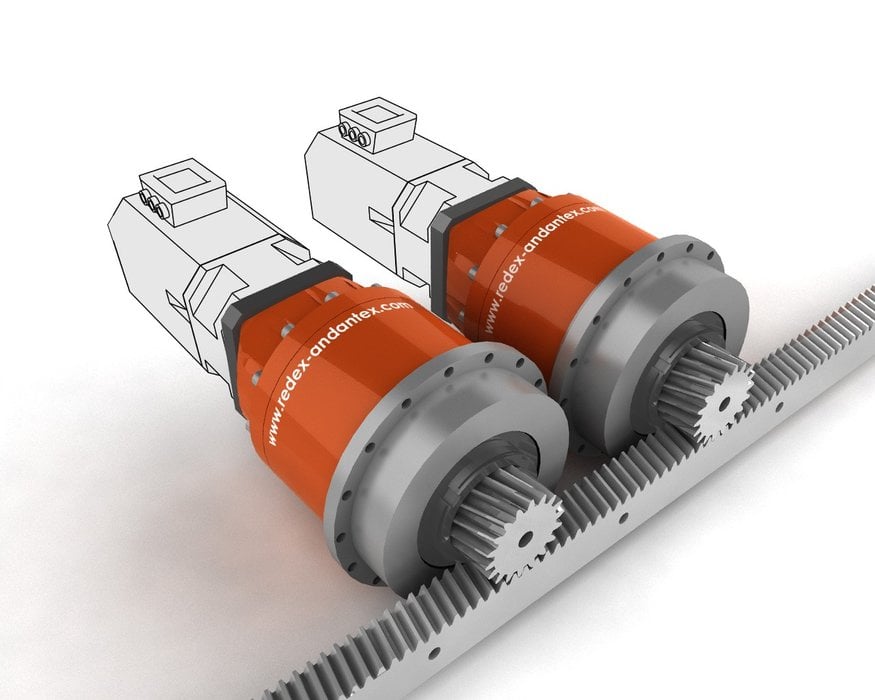

A TwinDRIVE KRPX is made of two planetary reducers, designed to be mounted on both sides of a standard machine frame.

Fixation is made by oversized screws to ensure a real still connection with the machine frame. Used as an extension to the main frame of the machine, the KRPX housing is made of high quality spheroidal graphite cast iron. Its structure has been optimised with FEM analysis methods to avoid deflection during acceleration. This smart system has been designed to eliminate any risk of mounting system deflection.

The new KRPX version was original created to simplify the servo-reducers assembly design for fixed-bed and travelling column machines, although, like in X axes of moving table Correa | VERSA model, other configurations can take advantage of this new concept. When backlash is cancelled on a the relevant axis by means of a master-slave system with electrical preload, the placement of a reducer backed up against each side of the column often involves the elimination of intermediate assembly elements that can decrease the global stiffness system and complicate both the design and the assembly of the servo-reducers.

ANAYAK has incorporated this solution into the HVM travelling column milling machines, leading to a saving of 2 Tons in weight in the basic design of the column.

CORREA has incorporated the solution in the X axis of the new VERSA range, and because there is no need to design and manufacture a mounting system, the implementation is much simpler and cost-effective (cost savings up to 15%).

Like all racks & pinions servo-reducers from the REDEX ANDANTEX range, KRPX version includes the right angle version and all possibilities for motor flanges as standard options.

Pic 2: Correa|VERSA W bridge-type milling machine with travelling table and lifting crossbeam

Pic 3: Typical mounting arrangement of the new TwinDRIVE KRPX system

Pic 4: TwinDrive KRPX Rack&Pinion system used in X axes of moving table Correa|VERSA

Pic 5: Standard KRP+ version

Nicolás Correa has just updated its current range of bridge-type milling machines with the new high-performance family called VERSA.

This model is equipped with a full range of interchangeable heads, among which is the mechanical universal head with a resolution of 0.02º and a rated speed of 6,000 rpm (UAD). This patented head offers better repeatability and locking force than conventional systems.

High performances linear drives in a wide range of bridge type machines

Worthy of note is the Correa | VERSA travelling table model, which has a work area of up to 14,500 x 5,000 x 1,500 mm. The Correa | VERSA M travelling bridge version and its variant the Correa | VERSA MW with adjustable crossbeam offers even greater versatility for the optimal machining of large structural elements and tools while retaining the rigidity and precision specific to the gantry architecture.

This new family of bridge-type machines incorporates the most recent advances on the market in terms of the guide systems and drives of the different axes, as well as the structural elements that offer greater dynamics, precision and damping in machining work. Using the most appropriate drive system is therefore a keypoint and Nicolás Correa has found in REDEX ANDANTEX a specialist supplier of rack & pinion drive systems for machine tools. The X and Y axes are therefore fitted in standard with this manufacturer’s drive systems.

Exceptional technical features

On the X axis, these drives are capable of moving a mass of 50 Tn with an acceleration of 1.8 m/s2, although they are capable of moving a mass of 70 Tn depending of the customer’s needs. Speeds in the X and Y axes are 30 m/min.

To cancel out backlash in the 2 axes, Nicolás Correa has opted for the TwinDrive system. It consists of a master-slave electronic configuration (electrical preload), with 2 motors.

The rigidity of the reducers together with the “true integrated pinion concept” (REDEX ANDANTEX patent) provides to Versa machine incomparable KV values to the CNC:

X-axis: KV=1 with 50000 kg of moving mass

Y-axis: KV=2 with 9200 Kg of moving mass

As a consequence, machine is able to reach the highest dynamic levels and optimal control response, resulting in greater positioning precision. A closed-loop system is implemented thanks to a Heidenhain linear encoder achieving following features:

X-axis: repeatabily = 5 microns ; Precision = 7 microns

Y-axis: repeatabily= 4 microns ; Precision = 6 microns

Versa X axis moves with an acceleration of 1.8 m/s2, a 50t travelling table with a repeatability of 5 microns

Concurrent development and multiple partnerships

The racks are manufactured by Swiss company Güdel, REDEX ANDANTEX business partner in a number of countries, such as Spain. High precision racks are the perfect technological partner for the servo-reducers, providing the lowest pitch error on the market in tempered and rectified commercial racks.

“With this new range of milling machines, we have incorporated REDEX ANDANTEX rack & pinion drives in the Y axis for the first time and proven that interpolation with the X axis has improved compared with the previous ball screw solution” – explains Javier Hernando, I+D Director of Nicolás Correa.

Nicolás Correa also fits REDEX ANDANTEX rack & pinion drive systems in the high-speed floor-type HVM-HS moving column milling machines of the ANAYAK range. This range is designed for machining medium and large-sized parts.

“Working with REDEX ANDANTEX, we have found the perfect partner that meets our expectations, not only in terms of product quality and reliability, but also in terms of their before- and after-sales service, which provides us with significant added value” – remarks Javier Hernando.

A new mounting concept allowing much simpler assembly

Amongst other machine-tools OEMs, the answer to Nicolas CORREA’s needs in terms of racks & pinions drive systems did lead REDEX ANDANTEX to increase its TwinDrive range of products with the new KRPX. This new version will be officially introduced during the next EMO 2009.

A TwinDRIVE KRPX is made of two planetary reducers, designed to be mounted on both sides of a standard machine frame.

Fixation is made by oversized screws to ensure a real still connection with the machine frame. Used as an extension to the main frame of the machine, the KRPX housing is made of high quality spheroidal graphite cast iron. Its structure has been optimised with FEM analysis methods to avoid deflection during acceleration. This smart system has been designed to eliminate any risk of mounting system deflection.

The new KRPX version was original created to simplify the servo-reducers assembly design for fixed-bed and travelling column machines, although, like in X axes of moving table Correa | VERSA model, other configurations can take advantage of this new concept. When backlash is cancelled on a the relevant axis by means of a master-slave system with electrical preload, the placement of a reducer backed up against each side of the column often involves the elimination of intermediate assembly elements that can decrease the global stiffness system and complicate both the design and the assembly of the servo-reducers.

ANAYAK has incorporated this solution into the HVM travelling column milling machines, leading to a saving of 2 Tons in weight in the basic design of the column.

CORREA has incorporated the solution in the X axis of the new VERSA range, and because there is no need to design and manufacture a mounting system, the implementation is much simpler and cost-effective (cost savings up to 15%).

Like all racks & pinions servo-reducers from the REDEX ANDANTEX range, KRPX version includes the right angle version and all possibilities for motor flanges as standard options.

Pic 2: Correa|VERSA W bridge-type milling machine with travelling table and lifting crossbeam

Pic 3: Typical mounting arrangement of the new TwinDRIVE KRPX system

Pic 4: TwinDrive KRPX Rack&Pinion system used in X axes of moving table Correa|VERSA

Pic 5: Standard KRP+ version